In the photovoltaic industry, electrical inverters play a crucial role in converting solar energy into usable electricity. However, it is important to ensure that these devices are in optimal condition and free from electrical leakage. In this article, we will explore the importance of leakage testing power inverters and how this process is carried out.

The function of power inverters

Electrical inverters are responsible for converting the direct current generated by solar panels into alternating current, which is the form of electricity used in most homes and businesses. These devices are essential for the correct operation of photovoltaic systems, as they allow the captured solar energy to be used to its full potential.

Potential problems of leakage

Electrical leakage in inverters can be problematic due to several factors. Firstly, they can compromise the safety of both operators and installations. In addition, leakage can affect the performance and efficiency of inverters, resulting in lower energy production.

It is also important to note that leakage can damage other components of the PV system, leading to additional repair or replacement costs.

Impact on the PV Industry

Inverter leakage testing is essential to ensure the reliability and optimal performance of PV systems in the industry. An undetected leakage can lead to system malfunction, decreased energy production and possible damage to other grid-connected equipment. Therefore, regular leakage testing is essential to avoid economic losses and to ensure a sustainable and safe energy supply.

Types of leakage testing for power inverters

There are several methods for leakage testing of power inverters to assess their electrical integrity. The main ones are presented below:

Insulation resistance tests

Insulation resistance tests are used to verify the insulation resistance of electrical inverters. These tests involve applying a DC voltage and measuring the current flowing through the insulation. The results help determine if there are any leaks or weaknesses in the insulation, which could lead to electrical problems.

Continuity tests

Continuity tests focus on verifying the existence of a continuous electrical conduction path in inverters. They are used to detect possible short circuits or interruptions in the internal circuits of the electrical inverters. These tests are performed by applying a DC and measuring the electrical resistance at different points in the circuit.

Dielectric strength tests

Dielectric strength tests are used to assess the ability of electrical inverters to withstand high-magnitude voltages without insulation failure. In these tests, a high-frequency voltage is applied and the current flow is monitored. The results determine whether the inverters can withstand high voltage conditions without electrical leakage.

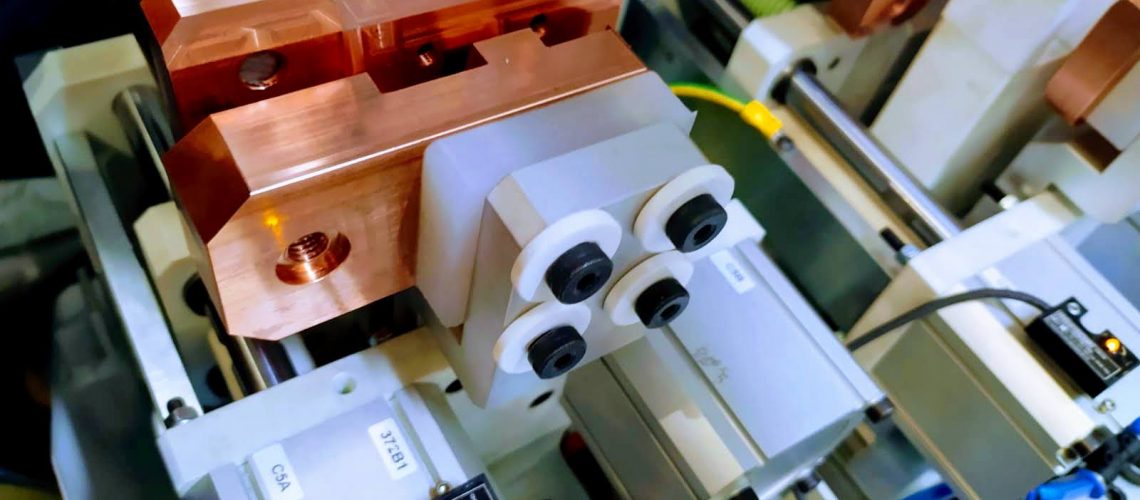

Equipment used in leak testing

Inverter leakage testing requires the use of specialized equipment to ensure accurate and reliable measurements. Some of the most common equipment used in this process are listed below:

Megometers

Megometers are used to measure the insulation resistance of electrical inverters. These devices apply a DC voltage to circuits and measure the insulation resistance. The results are expressed in ohms and provide information on the quality and integrity of the insulation.

Insulation analyzers

Insulation analyzers are more advanced instruments that allow testing of insulation resistance, continuity and dielectric strength. These devices offer a wide range of functions and configurations, making it easier to detect leaks and electrical problems in power inverters.

High voltage generators

High-voltage generators are equipment used in dielectric strength testing. These generators produce high-magnitude voltages that are applied to electrical inverters to assess their ability to withstand high-voltage conditions without electrical leakage.

The leakage test procedure for power inverters

Leakage testing of power inverters follows a systematic procedure to ensure accurate results. The following is a general process that can be followed:

Equipment preparation

Before starting the tests, it is necessary to ensure that the equipment used is in good working order and properly calibrated. The proper connections and configurations of the measuring instruments must be verified.

Connection of the electrical inverter

The electrical inverter must be disconnected from any external power source and the manufacturer’s instructions must be followed to ensure proper connection. This involves connecting the test leads to the appropriate terminals on the electrical inverter.

Execution of the tests

Once the electrical inverter is correctly connected, the appropriate leakage tests can be performed. This involves applying the appropriate voltage or current according to the type of test and measuring the results using the appropriate measuring equipment.

Interpretation of results

After testing, the results obtained should be analyzed. In general, look for high insulation resistance, adequate continuity and satisfactory dielectric strength. Any abnormal values or values outside the established limits may indicate the presence of leakage or electrical problems in the inverter.

Benefits of leakage testing of power inverters

Inverter leakage testing offers several important benefits for the PV industry. Some of these benefits are:

Prevention of major damage

Early detection of leaks in power inverters allows corrective action to be taken before major damage occurs. This can prevent catastrophic and costly failures in the PV system as well as possible damage to other connected equipment.

Improved efficiency and reliability

Regular leakage testing ensures that power inverters are in optimal operating condition. This contributes to higher efficiency and reliability of the overall PV system, resulting in higher energy production and better long-term profitability.

Compliance with regulations and standards

Leakage testing of power inverters is a requirement in many regulations and standards in the PV industry. Performing these tests regularly and documenting the results ensures compliance with legal requirements and electrical safety standards.

Safety considerations

When leakage testing power inverters, it is essential to take safety considerations into account. Some important guidelines include:

Use of appropriate equipment

The use of appropriate and high-quality test equipment is essential to ensure the safety of both personnel and equipment. Instruments must be properly calibrated and appropriate for the specific tests to be performed.

Staff training

Personnel involved in leak testing should be properly trained in the use of the equipment and in the required safety measures. This includes knowledge of test procedures, interpretation of results and precautions to be taken during testing.

Compliance with electrical safety regulations

It is important to comply with applicable electrical safety regulations and standards during leakage testing. This involves following established guidelines, using personal protective equipment when necessary and ensuring proper disconnection of electrical inverters during testing.

Frequently Asked Questions (FAQs)

How often should leakage testing of power inverters be carried out?

The frequency of leakage testing of power inverters may vary depending on the manufacturer’s recommendations and local regulations. In general, it is recommended to perform these tests at least once a year or at regular intervals to ensure the electrical integrity of the inverters..

What are the risks of not carrying out leakage testing?

Failure to leak test power inverters can lead to serious problems, such as electrical failures, damage to other equipment and loss of efficiency in the PV system. In addition, there is a safety risk for both operators and the facility in general.

Can I carry out leakage testing on inverters myself?

While some simple tests can be performed by trained personnel, it is advisable to have professionals specialized in leakage testing of power inverters. These experts have the knowledge and experience to carry out accurate and reliable tests, thus ensuring optimal results.

What regulations and standards must be followed during leak testing?

Regulations and standards may vary by geographic location and specific industry. Some common regulations include electrical safety regulations and guidelines established by recognized PV organizations. It is important to keep up to date with applicable regulations and ensure that you comply with them during leakage testing.

How can I find a qualified professional for leakage testing of electrical inverters?

To find a qualified professional, you can search for companies or consultants specialized in electrical maintenance and testing services in the PV sector. It is advisable to check the experience and certifications of the professionals, as well as reviews and references from other customers before making a decision.

Conclusions

Inverter leakage testing is a fundamental part of the maintenance and safe operation of PV systems in the industry. Identifying and addressing electrical leakage, improves system efficiency and reliability, prevents further damage, and complies with applicable regulations and standards. Regular testing and trained professionals are important to ensure accurate and reliable results.